6900 Hunters Knoll Remodel Project

January 23rd

Completion date estimate +84 .. and counting...

Today is HYDRAULIC LIFT DAY!

If you've been following along closely, you'll remember that the hydraulic lift that I plan to use to "stack" two Corvettes in the new garage was delivered on December 12th (after suitable obsessing). If you'll look on the December 12th page you'll see the lift placed by the forklift in the garage.

The packaging of the lift (which weighs 1500 lbs.) was cardboard wrapped around the lift parts and the whole thing shrinkwrapped. Because I couldn't begin to build the lift until the garage was finished (painting and all) it just sat there until last night.

I emailed a bunch of friends and invited them to a "Lift Party" (sorta like a barn-raising) for today. I didn't mention heavy lifting but I did mention beer -- so a

number of folks turned out; here's the list:

Brian Atkins

Don Kasten

Frank & Sandy Fortson

Joe Blumberg

Mase Sanford

Mike McDermott

Rich Wolf & Ina Thompson

Ted Aspes

Tom Smart

Tommy Powell

Wally White

They have my undying gratitude!

You see, the heaviest piece of the lift weighs about 350 lbs. so I needed lots of manpower to do the job. But I digress.

| This is the lift last night before I removed the shrinkwrap. |

|

| And this is after the shrinkwrap but before the cardboard was removed |

|

| And this is with all the small pieces stacked on top. This was about as far as I could go without help. |

|

This is where I got my first big surprise: There were NO !@#$%$#! INSTRUCTIONS!

That's right. No assembly instructions, no parts list, no nuthin'.

I thought surely (don't call me "Shirley") that Autolifters would have included assembly instructions -- but, no. Not one to panic, I waited until my heart-rate returned to semi-normal and phoned them (it's now 9pm Friday night) -- but, of course, they have no 24/7 customer service. I called a friend, Bill Anstine who has three of these things in his garage) -- and he didn't have the instructions either. He kindly went into the garage and photographed the lift in finished condition -- but somehow the images never made it through the email system. Bill assured me that even without instructions, it ain't that hard to figure out. Easy for him to say...

Being a REAL man (and having no other choice), I elected to go forward WITHOUT

the benefit of instructions.

("INSTRUCTIONS?!? We don' need no stinkin' INSTRUCTIONS!")

| This is where it's going to go. If you're looking down on the garage, the lift goes in the back left corner. |

|

| The first step was to unbolt the top track from the heavy steel pieces that were used as the ends of the package. Then the track could be moved (right!) with several folks. Left to right, that's Mase Sanford, Ted Aspes and Frank Fortson.

|

|

| Left to right, this is Ina, Ted, Brian, Tom, Mase, Rich, Mike and Frank (his head, that is). The one of the two red tracks is lying on the floor and the four posts are being put in place. They just stand on the floor (no bolts). |

|

| The posts are up and both tracks are bolted to the crosspieces. From left to right, Rich, Ina, Ted, Brian, Mase, Wally and Joe. You get to see backs of heads a lot. |

|

| This is Brian (shoulder) Tom, Mase, Mike and Frank. This post holds the motor that drives the pump that pumps the hydraulic fluid into a piston/cylinder under the left-most track. This in turn pulls a set of four cables, one at the top of each post. Collars attached to the cross pieces ride the posts and it all goes up and down.

That's the theory. |

|

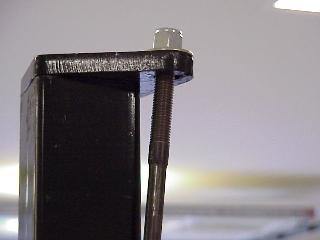

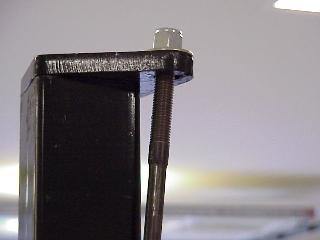

| This is the top of a post showing the threaded cable terminator. These four cables take all the weight but have a multi-pulley mechanical advantage. The lift is rated at 6000 lbs. so my 3000 lb. Corvette won't tax it much. |

|

| Despite the lack of instructions, I have to admit that the lift is pretty thoughtfully made. There is a guard over each of the exposed pulleys for safety sake |

|

| Quite a long time was spent trying to figure out whether the hydaulic fluid reservoir had anything in it and, whether it did or not, how you could add fluid. And it took forever to determine that the piston had to be pulled out of the cylinder all the way (about 4 feet) before the pump would work properly. Don went for 5 gallons of fluid (we needed it). |

|

| Here's the slack cables finally attached to the end of the piston. It's downhill from here. Plug in the motor, push the button, wait a while for the air to bleed out and the fluid to pump in. |

|

| And yes, ladies and gentlemen, it's goin' up! |

|

| And what goes up, must come down. Without the weight of a car to help it along, Mike and Brian volunteered to act as supercargo since gravity is the "down" force... |

|

| Here's the first practical use of the new lift. This is Brian's Navy C5 Corvette on the lift to install an accessory under the car. Cool! I didn't mention it but the lift has wheels that can be bolted on so the whole thing can be moved with or without a car on it. We moved it to the middle of the garage for this work. |

|

| And, while we were at it, this is Mike's Black C5 Corvette having its factory exhaust system replaced with an after-market Corsa Touring exhaust. The difference in the sound is awesome; and it only took an hour and a half! |

|

| And here's a pretty happy Mike with his new Corsa Touring exhaust installed. |

|

|